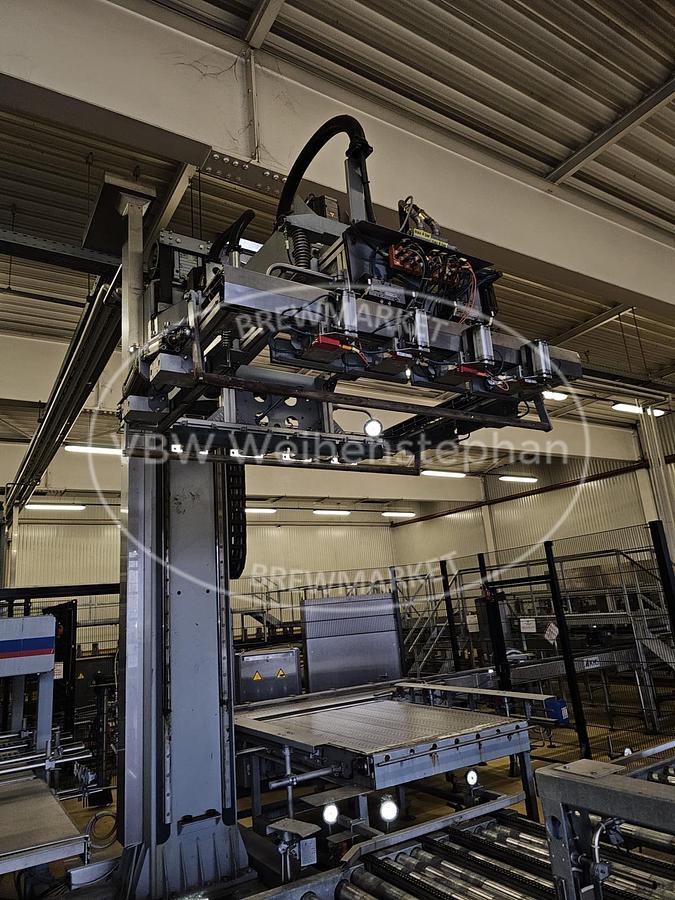

Depalletising and palletising system as a combination machine

No longer available

Depalletising and palletising system as a combination machine

Description

Depalletising and palletising with a gripper head:

1 - 2 full pallets can be placed on the right-hand pallet table (= forklift driver's view). From there, they run to the left to the turning segment, are turned lengthways and then conveyed into the depalletiser. The gripper head lifts the crates layer by layer onto the ‘unloading table’, from where they are conveyed away. When the pallet is empty, it is temporarily stacked in the magazine or continues directly to the loading station. On the other side of the gripper tower, the module boxes are pushed onto the grouping plate and stacked layer by layer on the pallet. When it is full, it runs to the turning segment and is then stopped on a 2-position delivery table.

Specifications

| Manufacturer | KHS |

| Year | 2007 |

| Condition | Used |

| Stock Number | 209747HG |

| Additional title | Space-saving depalletising and palletising with one gripper head |

| Capacity | 1000 crates/h |

| Air consumption | 12 Nm³/h |

| Power | 15 kW |

| Current | 47 A |

| Compressed air | 6 bar |

| Formats | Euro pallets (1200 x 800 mm), Modular crates (400 x 300 mm) |

| Operation / Control | KUKA robot control system |

| Position | free-standing |

| Base construction | Square tube construction on dome feet |

| Features | 2 pallet loading table, 2 pallet rotating segments, pallet magazine, 2 pallet delivery table, tower with gripper head, box delivery table, box grouping table, box transport, barrier grid, control cabinet, on-site control device |

| Layer patterns | 3 x 2 crates/layer, 4 layers |