Entpalettierung - Leergutsortierung

nicht verfügbar

Entpalettierung - Leergutsortierung

Beschreibung

Entpalettierung/Leergutsortierung:

Die Leergutpaletten werden auf einem 6-fach Aufgabetisch abgestellt, nacheinander ins Gebäude befördert und dort entpalettiert. Die Kisten durchlaufen einen Kontrolleur der in "gutes" und "fremdes/fehlerhaftes" Leergut trennt. Die "Guten" laufen direkt zum Auspacker vor der Waschmaschine. Die "Schlechten" laufen zu einem separaten Auspacker. Die leeren Kisten werden danach über einen Kastenwender und -Kontrolleur zum Einpacker der guten Flaschen befördert. Die Flaschen werden zu einem Flaschen-Inspektor befördert, welcher Fremd- und fehlerhafte Flaschen aussortiert. Die aussortierten Flaschen laufen zu einem Einpacker, werden in Kästen eingepackt, auf Palette gestapelt und aus dem Gebäude befördert. Die guten Flaschen werden einem Einpacker zugeführt, in korrekte Kasten eingepackt, und in Richtung Auspacker vor der Waschmaschine weitertransportiert.

Die Leistung der Entpalettierung liegt bei

3200 Gebinde/h ( ca. 64.000 / 76.800 Fl/h )

Die Leistung der Leergutsortierung liegt bei

50.000 - 60.000 Fl/h ( am Auspacker )

Die Anlage besteht aus:

Entpalettierung

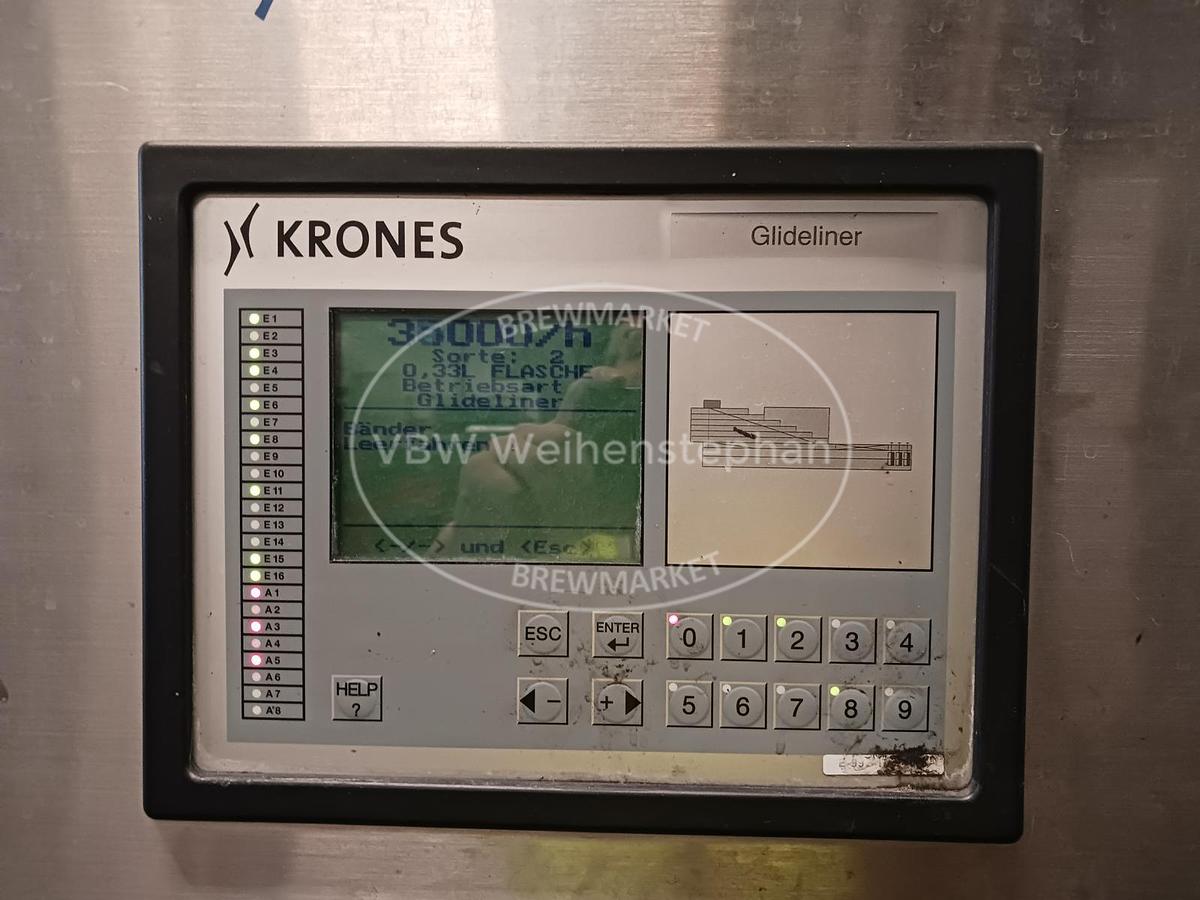

Hersteller: Fa. Krones

Modell: ROBOT Linear 2A

Auspacker

Hersteller: Fa. Krones

Modell: Junior A 4 T

Einpacker

Hersteller: Fa. Krones

Modell: Junior E 4 T

Halbautomatischer Neuglasabheber

Hersteller: Fa. Krones

Modell: 1P

Kastenwender

Hersteller: Fa. Krones

Modell: MultiCo

Flaschentransport

Hersteller: Fa. Krones

Modell: SYNCO S

Einpacker/Belader

Hersteller: Fa. Krones

Modell: ROBOGRIP

Die Paletten-Abgabe mit Rollbahnen und Palettenbinder, sowie die Kontrollgeräte für Leergut-, Leerkasten- und Flaschen-Inspektor sind nicht enthalten.

Spezifikationen

| Hersteller | Krones |

| Jahr | 2005 |

| Zustand | Gebraucht |

| Artikelnummer | 209909HG |

| Maschine (Zusatz) | mit Leergutrückführung |

| Leistung | 60000 Fl/h am Einpacker |

| Bedienung / Steuerung | SPS, Bedienschränke mit Touch-Panel |